2020 Outstanding Civil Engineering Achievement Award

[Group-1]

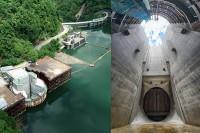

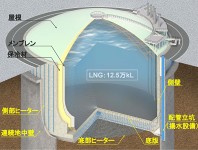

1.Productivity Improvement by Introducing Large-Scale All-Precast Method for PC-LNG Storage Tank Construction

- Tokyo Gas Co.,LTD. Energy Production Dept.

- Tokyo Gas Engineering Solutions Corp.

- IHI Plant Services Corp.-Kajima Corp. Joint Venture

One of the important issues in LNG tank construction is to shorten the construction period. In order to shorten this period, precasting of the outer tank is an effective means, and it also improves the quality of the structure and the stability of the construction process. In the Hitachi LNG Terminal II of Tokyo Gas Co., Ltd. we applied Japan's first all precasting technology to prestressed concrete outer tank of one of the largest aboveground LNG storage tanks in Japan, and demonstrated the effectiveness of the new technology by drastically shortening the construction period and saving labor compared to the conventional in-place casting method.

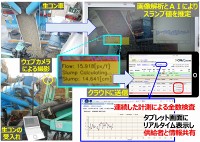

2. Productivity Improvement with the Use of Digitized Information on Ready-mixed Concrete and Realization of Advanced Quality Control by 100% Inspection and CIM implementation – Amagase Dam Redevelopment Tunnel Inflow Section Construction Work –

- Ministry of Land, Infrastructure, Transport and Tourism Kinki Regional Development Bureau Biwako Office

- Taisei Corporation

In the Amagase Dam Redevelopment Tunnel Inflow Section Construction Work, a new ICT/CIM system is implemented and demonstrated its effect on improvement of productivity and quality control. This system includes data sharing of ready-mixed concrete on cloud storage, e.g., information of delivery and receiving, 100% inspection record utilizing AI based image analysis technology and automatic recording of construction process, such as placement and overlaying layer. This helps all of concrete manufacturers, contractors and ordering parties share the real-time information on construction status. JSCE award was given to this achievement recognizing productivity improvement through information sharing and implementation of innovative technology.

3. Invention of Pipe Roof Construction Method Applicable to Geology Including Large Boulder (Kyusyu Shinkansen Isahaya Tunnel)

- Japan Railway Construction, Transport and Technology Agency

- Toda Corp.

The Kyusyushinkansen Isahaya Tunnel is a 230m-long tunnel for Shinkansen high speed rail with the width of double track and excavated 3.5m below National Road Route-207. Route-207 has daily passage of 25,000 vehicles and contains many buried utilities such as water and sewage, electric power, communication, and gas. In such a shallow overburden, open cut method has been generally applied. But considering the difficulties of replacement of utilities and less disturbance on the road traffic, the mountain tunneling method was applied in this case. In this construction, a jointless pipe roof “Backfill Wrap Construction Method” was devised to tackle the soft geology with hard boulders as auxiliary support in the mountain tunneling system. This method will increase available options for more effective auxiliary support in mountain tunneling and thus contribute to the development of high-quality infrastructure.

4. Challenging Shield Tunnel Construction to Put All Equipment Underground in Consideration of the Surrounding Environment

- Mitsubishi Estate Co., Ltd.

- Marunouchi Heat Supply Co., Ltd.

- Mitsubishi Jisho Sekkei Inc.

- Taisei Corp.

Two shield tunnels were constructed with vertical shafts directly underneath the Marunouchi Nakadori street in Chiyoda, Tokyo, one of Tokyo's most vibrant day-and-night commercial areas. In this construction, ingenuities were exercised for the surrounding environment: In addition to the design review to shorten the construction process, the equipment was installed in the shafts to realize landscape consideration and noise reduction at the same time. The fence on the ground was decorated to integrate it with the surrounding environment. The technical considerations implemented here will contribute to the future development of shield tunnelling in the limited small construction area and are considered suitable as a technical award of the JSCE.

5. “Optimized Drilling of Ikari Gravity Concrete Dam”: Vibration-Free Large-Block Pulling Out Method and Unmanned Machines through Continuous Hole Slit

- Ministry of Land Infrastructure and Transport and Tourism, Kanto Regional Development Bureau Kinugawa Integrated Dam Control Office

- Taisei Corp.

The Ikari Dam is a 112 m-tall gravity concrete dam, completed in 1956. This renovation project involved the construction of new “selective water intake system”, “water diversion and discharge system”, and “hydroelectric power generation system”, very difficult works to carry out in high and narrow spaces, with limited construction period. Drilling of the concrete dam - key to the construction - was completed on schedule without accidents, thanks to adopting the vibration-free large-block pulling out method and introducing unmanned machines. We expect future dam rehabilitation and other concrete structure improvement projects to apply this technique to make a social contribution.

6. The Flood Control Operation of Kusaki Dam during the Typhoon No. 19 in 2019

- Japan Water Agency

An unprecedented large-scale pre-release was carried out at Kusaki Dam during the Typhoon No.19 in 2019. For the implementation of this pre-release, extensive flood control experiences and the latest technological development by Japan Water Agency (JWA) were fully demonstrated; JWA has the runoff prediction systems that can predict up to 72 hours ahead in all dams. In addition, the operation training during floods is repeatedly conducted for engineers using the Dam Operation Training Simulator developed by JWA. This result shows that accurate pre-release is an excellent way to make more effective use of the flood control function of existing dams.

7. Early Completion of Excavation in the Long Mountain Tunnels through Increased Productivity (Reconstruction Support Road: Miyako-Morioka Crossroad Shinkuzakai Tunnel Construction)

- Kajima-Tokyu Construction Joint Venture

Shinkuzakai Tunnel is a long road tunnel with an evacuation tunnel. By taking advantage of this feature, the construction period was shortened by excavating the evacuation tunnel in advance and excavating from four faces of the main tunnel, which was branched off from the service tunnel towards the main tunnel. In addition, the four-boom fully-automatic computer jumbo (XE4C) adopted firstly in Japan, has been installed to enable safe and high-quality tunneling by utilizing of long-hole blasting and ICT.

8.The Development and the Construction of DAYFREE- the New Technology for the Bridge Deck Replacement under Nighttime Lane Closure (Chuo Expressway Yumifuri River Bridge Deck Replacement Project)

- Central Nippon Expressway Co., Ltd Hachioji Branch

- Obayashi Corp.

‘DAYFREE’ is the new technology for the bridge deck replacement. It enables that the decks are replaced under the nighttime one lane closure to avoid the traffic congestion, so it is very effective measure especially for urban area projects on heavy traffic routes. A lot of unique technologies for the DAYFREE (i.e. Highway strider, Slim NEO Plate) have been developed and adopted. DAYFREE was applied to the YUMIFURI river bridge deck replacement project and its feasibility and applicability on the real project were confirmed.

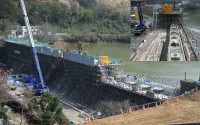

9. The Nam Ngiep 1 Hydropower Project in Lao PDR - Glorious Dam Construction Technology Forking World‐Classed Fastest Construction and Japanese-styled Highest Quality Control and Establishment of Innovative Resettlement Livelihood Model -

- The Kansai Electric Power Co., Inc.

- Obayashi Corp.

The Nam Ngiep 1 Project is an innovative hydropower project in Laos, applying the split-contract scheme with design risks taken by the owner to reduce cost, and contracting with internationally-competent Japanese contractors to minimize the construction risks. Several epoch-making concepts were realized to overcome serious risks materialized during the construction period by close collaboration with the owner and the contractors: - highly-skilled “All-Japan” organization; - continuous roller-compacted concreting with sloping layer method applied for dam placing, a fastest method convenient for rainfall treatment; - new Hybrid Method applied for curtain grouting, a simplified method using a single and high cement mix and high injection pressure; - ingenious education program provided to multinational workers for efficient quality control; and - inhabitants-oriented resettlement and livelihood programs led by the Japanese staff. The project has been awarded a strategic promotion model contributable to economic growth of the developing countries under the competent private infrastructure business overseas.

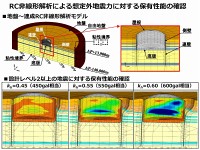

10. Advanced Application of RC Nonlinear Analysis Technology to Actual Design - Futtu Thermal Power station No.9, No.12 Inground LNG Storage Tank -

- Tokyo Electric Power Company Holdings, Inc.

- JERA Co., Inc.

- TAISEI Corp.

RC nonlinear analysis was utilized for Futtu thermal power station No.9,No.12 Inground LNG storage tank from detailed design stage to design the most cost effective underground tank in the world. This is first time in Japan for new LNG inground LNG storage tank. Performance checking technique using stresses and strains from the result of RC nonlinear analysis was introduced for load bearing performance evaluation in Level 2 earthquake. RC nonlinear analysis checking against unexpected seismic force of Level 2 earthquake or above were made as a new attempt. These results were highly evaluated as pioneering examples that can be applied to other structures. Achievements were regarded as contribution of the development of RC nonlinear analysis for design application and were recognized as deserving technical awards.

11.Adoption of the ECI Contract Method for the Kumamoto Earthquake Disaster Recovery Project

- Kumamoto Office of River and National Highway, Kyushu Regional Bureau, Ministry of Land, Infrastructure, Transport and Tourism

- Hazama Ando Corporation・Marusho Construction Joint Venture

- Shimizu Corporation・Fukuda Corporation・Matsushita Corporation Joint Venture

In 2016, the Kumamoto earthquake caused serious damages to several parts of Kumamoto prefecture. Along the Route 57 which connecting Kumamoto and Oita prefectures, huge landslides occurred and caused devastating disasters such as the cutting off the road and destroying the Aso-Ohashi Brige. These damages to the transport network become a major obstacle to the regional revival and it is vital to recover it as soon as possible. After considering the opinions of Kumamoto Prefecture and local governments, the construction of “Futaenotouge Tunnel”with length 3.7km which is part of the 13km of the Northern Restoration Route was proceeded to ensure smooth connection between Ozu Town and Aso City. During tunnel excavation, challenges such as low ground cover (9m) and large cavity were encountered but were managed quickly and appropriately. By adopting ECI(Early Contractor Involvement)system, it shorten the construction period and the entire restoration route successfully open to the public in October 2020.

12. Optimization of Design and Construction for Further Development of the Open-cut Construction Method Tokyo Outer Ring Road Chuo JCT North Ramp Project

- Ministry of Land, Infrastructure, Transportation and Tourism. Kanto Regional Development Bureau.

- Obayashi Corp. Tokyo Main Office

- OHMOTO GUMI CO., LTD. Tokyo Branch

Tokyo Outer Ring Road Chuo JCT North Ramp Project is design and construction works for improvement of Chuo JCT which connects the Outer Ring Road and Chuo Expressway / prefectural road. We proposed and constructed a large-scale composite box culvert structure (80m width, 257m length and 20~40m depth) containing 7 lamps with a combination of the open-cut construction method and the pneumatic caisson method. In this project, the design and construction departments worked closely together from the design stage to optimize the entire project considering not only economic efficiency but also quality, safety and environment.

13. Construction of the First Underground Metro Line in Vietnam by Shield Tunnelling Method

- Shimizu Corp.

- Maeda Corp.

The first underground metro line in Vietnam was constructed as part of the Ho Chi Minh City Metro Line 1 Project, using an EPB (Earth Pressure Balanced) type shield tunnel boring machine. Several technical challenges, such as tunnel excavation in a very loose and potentially liquefiable alluvial sand layer, and working in proximity to a sensitive, historical building, etc. required to be overcome by execution of effective countermeasures. Ensuring the quality of tunnel segmental lining in a local factory was another example of the challenges which were encountered. Throughout these processes, and in collaboration with the local project members, the works were completed successfully, and at the same time, significant contributions of providing technical knowledge transfer and quality infrastructure to Vietnam were achieved.

14. Development of Support System for Snow Blower Operation Using Quasi-zenith Satellite

- East Nippon Expressway Co., Ltd. Hokkaido Regional Head Office

- Nexco-Engineering Hokkaido Co., Ltd.

The rotary snow blower operated for removing accumulated snow on road shoulders must be performed properly even in the conditions such as a poor visibility due to a snowstorm for a winter highway safety. The operators of the blower, however, have to pay full attention to avoid contacting road structures and colliding with passing vehicles. Therefore, a high-precision snow blower positioning device using a quasi-zenith satellite and a high-precision expressway map has been developed for the first time in Japan. The device enables even unskilled drivers to control the snow blower safely and leads to cope with a future shortage of skilled drivers. Moreover, the device is now being adopted to challenge an autonomous snow blower development.

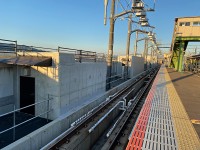

15. Cost-effective Tunneling by SENS which can Switch Lining Type from/to concrete Segment to/from Cast-in-place Lining - Hazawa Tunnel on the Eastern Kanagawa Rail Link

- Japan Railway Construction, Transport and Technology Agency Tokyo Regional Bureau

- Taisei, Tokyu, Omoto, Toshida Sotetsu-Tokyu though Line Hazawa Tunnel specified construction joint ventures

The Hazawa Tunnel is 3,150m-long tunnel with the width for double-track on urban railway connecting Hazawa Yokohama-Kokudai Station and Shin-Yokohama Station in Kanagawa Prefecture. This tunnel was excavated by the SENS (Shield, ECL, and NATM System), shield tunneling system with cast-in-place lining which had been originally developed for mountain tunneling. In this urban tunneling project, segment lining system was added to the SENS. Thanks to this improved SENS, segment lining could be applied under the foundation of bridges whereas less costly cast-in-place lining was in other parts. Thus economical lining type can be selected according to the site condition and this new SENS is proved to be applicable also to tunneling in urban areas.

16. Development and installation of the system to melt snow-ice adhered under bogies of Shinkansen train ~Akita shinkansen~

- East Japan Railway Company

- SENKEN KOGYO CO.,LTD.

- JR EAST MECHATRONICS CO., LTD.

- JR East Consultants Company

The Akita Shinkansen connect Tokyo with Akita in northern Japan, with direct service between two sections. The conventional line section (maximum speed 130km/h) is in heavy snowfall area, so snow adhere under the bogies of a train in winter. When a train was running in the Shinkansen section (maximum speed 320km/h), a problem happened that dropped snow-ice damaged the railway equipment. We tried to remove the snow-ice by human power, while a train stopping at a station, but it was difficult to remove it completely. To solve this problem, we developed the system which melts snow-ice by spraying hot water, and installed in Ogama station, located in end of heavy snowfall area. This made it possible to remove the snow-ice almost completely in a short time. This is the first system in Japan, which was developed in collaboration with several technical fields, track, machinery, electricity, and civil engineering.

17. Realize Parallelization of the Platforms 350m away at the Metropolitan Terminal Station under the Complicated and Diverse Construction Conditions (The second Rail Track Switching Work of JR Shibuya Station Improvement)

- EAST JAPAN RAILWAY COMPANY

- TOKYO NATIONAL HIGHWAY OFFICE, KANTO REGIONAL DEVELOPMENT BUREAU MINISTRY OF LAND, INFRASTRUCTURE, TRANSPORT AND TOURISM

- KAJIMA CORPORATION and SHIMIZU CORPORATION Joint Venture

- TAISEI CORPORATION and TOKYU CONSTRUCTION CO., LTD. Joint Venture

- TEKKEN CORPORATION, TOKYU CONSTRUCTION CO., LTD. and TOTETSU KOGYO CO.,LTD. Joint Venture

- KOTSUKENSETSU Corp. SHINJUKU No.2 CONSTRUCTION OFFICE

- KOMAIHALTEC Inc.

- KAWADA INDUSTRIES, INC.

- JR EAST CONSULTANTS COMPANY

- PACIFIC CONSULTANTS CO., LTD.

- JAPAN TRANSPORTATION CONSULTANTS, Inc.

In the second rail track switching work of JR Shibuya Station improvement, the track of Saikyo down line is moved up and to the side and Saikyo line platform is moved 350m for the transferability of passengers. The huge connecting passage girder was removed through the narrow space between the road bridge and the electric overhead wire, with lifting, lateral movement and descent by the suspension facility overnight. There being no precedent of switching the 422m track by transferring with 47 orbit girders, we've made elaborate preparations with 52 times trial construction. Completing the project with overcoming many obstacles has improved transferability of passengers greatly, the project was recognized as worthy of the award.

[Group-2]

1. Development Project of the Sea Embankment in the Hamamatsu City Coastal Area

- Shizuoka Prefecture

The sea embankment with a length of about 17.5 km and a height of 13-15 m was constructed in the Hamamatsu City coastal area to mitigate damage from the L2 tsunami. We constructed the wide trapezoidal shaped levee by using the cemented sand and gravel (CSG) method. This levee is stabilized against earthquakes and tsunamis, and makes it durable against tsunami overflow. Moreover, we could reduce costs by reusing excavated sand on site for CSG materials and streamlining a cross-section of CSG levee. In addition, the coastal disaster-prevention forest was regenerated on the embankment to preserve the environment. Also note that this project was funded by donations from companies and citizens of Hamamatsu City, and was implemented with the cooperation of Hamamatsu City Office and others.

2. The Takao River Diversion Tunnel Project - Construction of Diversion Tunnel Under and Along the River Winding Through Densely Housed Area -

- Fukuoka Prefecture

- Hazama Ando-Daiho-Kankyoshisetsu Specified Construction Joint Venture

The Takao River winds through densely housed areas that are regularly flooded by it during heavy rains, requiring urgent measures. However, conventional flood improvement methods require land acquisition which takes a long time. Therefore, an unprecedented method was used: the construction of a diversion tunnel under and along the river, using shield tunneling (Di=5m, L=1km). Despite the many difficulties, such as driving through hard weathered granite and driving 27 sharp continuous turns, the project was completed in a short period of only 5 years. This achievement can be a model for flood control in urban areas where it is difficult to secure land.

3. Asahigawa Divergent Channel “Hyakken River” Improvement Project

- Chugoku Regional Development Bureau Ministry of Land, Infrastructure, Transport and Tourism(MLIT)

The features of the Asahikawa flood bypass "Hyakken River" are in the "divergent point" and "river mouth barrage". At the river mouth, the latest technologies were applied for the water gate facilities in the Showa and Heisei eras respectively. It protects the Okayama plain which is almost zero-meter area from flood damages. Generally, the discharge flow at divergence point is controlled by large sluice gates. However, in Hyakken River, in order to preserve the valuable traditional and historical structures of the Edo era, we applied the fixed weir method with using model experiments and latest technology analysis. The Hyakken River improvement project was completed in the first year of Reiwa, taking more than half a century from the start of construction.

4. Construction of Metropolitan Expressway Kanagawa Route No.7 Yokohama Northwest Line (Direct Connection between Tomei Expressway and Yokohama Port)

- Metropolitan Expressway Co., Ltd.

- City of Yokohama

The Yokohama Northwest Line was planned with residents’ views through Public Involvement. The total length of the route is 7.1km, and the 60 percent was constructed underground. In tunnel section, large diameter shield tunnels were constructed underneath residential area. In viaduct section, environmental impact was reduced by various construction methods, and the oppressive feeling is minimized by improving the color and shape of structures. The original project period was 10 years, but it was shortened to 8 years by introducing Public Involvement and various construction technologies. Accordingly, it contributed remarkably to the improvement of civil engineering technology.

5. Wind Farm Tsugaru Project -Construction of the largest onshore wind farm in Japan-

- Green Power Investment Corp.

- Kajima Corp.

“Wind Farm Tsugaru”, located in Tsugaru City on the Japan Sea coast of Aomori Prefecture, is the largest onshore wind farm in Japan. The facility has 38 wind turbines×3.2MW with a total capacity of 121.6MW. This project has successfully contributed to the development of civil engineering technology for Japanese renewable energy industry, such as speed-up of the transmission lines installation, creating effective construction procedures for wind turbine foundations, and shortening the construction period for the turbine parts transportation and installation. All facilities were constructed over a period of just 34 months, and the commercial operation has commenced on April 1, 2020.

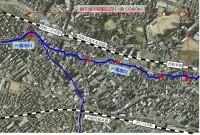

6. Transit-Oriented Urban Design at Toyama, by Cooperation of Various Projects; North-South Connection of Trams across the Shinkansen Toyama Station

- Toyama Prefecture

- Toyama City

- Japan Railway Construction, Transport and Technology Agency

On 21st March 2021, the project connecting divided tram into north and south in the city of Toyama was completed and through service started. This is a symbolic project of collaborative work by several public entities. In the opportunity of Shinkansen construction, divided tram line by existing railway was connected to function as a crucial transportation of ‘Compact City’. The city of Toyama, the Prefecture of Toyama, and Japan Railway Construction, Transport and Technology Agency were in a close partnership over their project boundaries and achieved this sagacious milestone for the future urban development. Reborn Toyama station is a regional key transport node combining inter-regional, intra-regional, and urban transportation. By this connection project, Toyama station can become a legacy to generate potentials of future urban development policy based on public transportation.

7. Waterfront Road North-South Line, Port of Tokyo, Development Project (Tokyo Port Umi-no-Mori(Sea Forest) Tunnel) ~ Undersea Tunnel Construction Work in a Short Period of a Time, Tunnel Element which is Longest in Japan ~

- Tokyo Port Office, Kanto Regional Development Bureau, MLIT

- Tokyo Metropolitan Government Bureau of Port and Harbor

Waterfront Road North-South Line, Port of Tokyo Development Project, the purpose of the construction is for responding to further increases in traffic such as container cars and secure of smooth logistic functions. In construction, it carried out Various construction methods and ingenuity for high-precision and reliable construction while shortening the construction period. In actual construction of the tunnel part, it shortened the construction period for immersed tunnel element by several construction methods, and it performed a three-dimensional simulation in installation of immersed tunnel element for high precision and reliable construction. It was evaluated and recognized as worthy of a technology award, that the technology of this project contributes for the secure of smooth logistics functions.

8. The Project for Improvement of Namibe Port in the Republic of Angola

- Oriental Consultants Global Co., Ltd.

- PADECO Co., Ltd.

- TOA CORPORATION

The Project for Improvement of Namibe Port was implemented in southern Angola with an aim to enhance transportation capability in the region by rehabilitating the deteriorated port facilities. The specific technical issues such as ensuring of toughness and reliability of the facility and smooth construction inside the port in service, were well addressed by additional survey and weekly coordination meetings. The project was completed one month ahead of the schedule without any accidents and contributed SDGs by job creation in the region. This was highly recognized by Angolan side. It is therefore evaluated and recognized as worthy of a technical award.

9. Sanru Dam Construction Project: The Northernmost Trapezoid-shaped Cemented Sand and Gravel (CSG) Dam with Riverbed Gravel as CSG Base Material

- MLIT Hokkaido Regional Development Bureau, Asahikawa Development and Construction Department

Sanru Dam in Hokkaido is the fourth trapezoid-shaped CSG dam in Japan. Borrow-pit distribution status of topsoil, base material and waste of riverbed gravel (CSG base material) was modeled in 3D. Machine guidance to sort base material, system to monitor particle size and volume of surface water during CSG production, and steep sandwich belt conveyor to transport CSG were adopted. Thanks to dam body quality assurance, and achieving dam body construction at low cost, with high quality and low environmental load, the construction of Sanru Dam is rated highly as a project that meets the social needs of our time.

10. The Construction of Kanchpur, Meghna, Gumti 2nd Bridges and Rehabilitation of Existing Bridges

- Government of the People’s Republic of Bangladesh Roads and Highways Department

- Oriental Consultants Global Co., Ltd.

- Japan Bridge & Structure institute, Inc.

- Katahira & Engineers International

- Nippon Engineering Consultants Co., Ltd.

- SMEC International

- Obayashi Corp.

- Shimizu Corp.

- JFE Engineering Corp.

- IHI Infrastructure Systems Co., Ltd.

This project consisted of the rehabilitation of existing bridges and construction of new bridges on National Highway No.1 connecting Dhaka, the capital of Bangladesh, with Chittagong, the second largest city. Using Japanese technologies such as The Steel Pipe Sheet Pile, Narrow Box Steel Girder and Steel Concrete Composite Deck Slab, many difficult problems were solved and the project was completed safely. The efforts of this project were recognized as worthy of the Technology Award, because it made a significant contribution to the development of civil engineering technology and society in Bangladesh by installing and transferring many Japanese construction technologies.

11. Rapid Reconstruction of an Expressway Bridge Swept away by Heavy Rainfall-induced Landslides. (Disaster Recovery and Reconstruction of Tajikawa Bridge and Other Facilities of Kochi Expressway)

- West Nippon Expressway Co., Ltd., Shikoku Branch

- Kajima Corp.

On the 7th of July 2018, superstructures of 63.5m long Tajikawa bridge were swept away after a destructive landslide of mountainside caused by days of record-breaking heavy rain in western Japan. Being a part of Kochi Expressway connecting Shikoku Island and the mainland of Honshu, it was vital to reconstruct the bridge in the least time possible to minimize direct and indirect economic losses arising from network abnormal operation and traffic disruption. A rapid reconstruction of the bridge was achieved by using precast prestressed concrete components and systems reducing the onsite construction time and resulting the expressway to be reopened to the public just one year after the disaster.

12. MRT Thomson-East Coast Line T226 Project, Singapore

- Land Transport Authority, Singapore

- Taisei Corp.

For construction of the new Thomson-East Coast Line project in Singapore, two railway tunnels in stacked configuration and a pedestrian linkway tunnel are constructed directly underneath two operating MRT lines. Three Japanese technologies, “Horizontal jet grouting”, “Open faced rectangular shield machine with compressed air” and “Ground freezing”, were adopted for the first time in Singapore to overcome the difficult and complex works for MRT construction. The combination of these technologies substantialized the underpinning of existing MRT structure and the construction of three tunnels. The works were completed successfully and safely owing to the combined efforts of the three professional parties, Design, Construction, and Instrumentation & Monitoring.

13. The Comprehensive Development Project of Hamada River -Initiatives for Hbrid Project through Construction of New Dam and Upgrading of Existing Dam-

- Shimane prefecture

- Kajima・Goyo・Imai JV for the construction project of 2nd Hamada dam

- Kajima・Fukuda・Shoyo JV for the upgrading project of Hamada dam

The Hamada River Comprehensive Development Project is to upgrade the existing Hamada Dam and construct the 2nd Hamada Dam in order to prevent flood damage in Hamada City. In the construction of the Second Hamada Dam, which is located about 2 km downstream from existing Hamada Dam, the water storage capacity of the entire project was secured about four times as effectively as before. This project, which will lead to a series of initiatives from business planning to design, construction, and management that takes into account local natural conditions and social environments.

14. Senbon Dam Reinforcement Work

- Matsue City Waterworks and Sewerage Bureau

- Japan Dam Engineering Center

- Chuden Engineering Consultants

- OBAYASHI Corp.

The Senbon Dam is a gravity-type masonry concrete dam constructed about 100 years ago, and has a high value as a historic structure, supplying about 1/4 of the tap water of Matsue City as a whole. In this project, seismic retrofitting by Prestressed Dam-use Anchors was carried out on the dam itself during one non-flood period as the first achievement in Japanese dams, while maintaining its water supply function and masonry landscape. It was recognized as worthy of this award for establishing effective renewal methods for aging infrastructure and conserving cultural heritage.

15. Delhi Mass Rapid Transport System Project Phase 1/2/3 "High-quality Infrastructure Development Project" that Instilled Awareness of Safety and Efficiency at Construction Sites in India and Provided Residents with Safe, Secure, and Comfortable Transportation

- (Executing Agency) Delhi Metro Rail Corporation Ltd.(DMRC)

- (Donor) Japan International Cooperation Agency(JICA)

- (Related Authority) Railway Bureau, Ministry of Land, Infrastructure, Transport and Tourism(MLIT)

- (Feasibility Study) Oriental Consultants Global Co., Ltd. (OCGlobal), Japan Railway Technical Service (JARTS)

- (General Consultant) OCGlobal, JARTS, Tonichi Engineering Consultants, Inc., Rites

- (Technical Cooperation) Tokyo Metro Co., Ltd.

- (Excavation and Underground station) Kumagai Gumi Co., Ltd., ITOCHU Corp.

- (Tunnel and Underground station) Shimizu Corp.

- (Rolling Stock/Electrical Equipment)Mitsubishi Corp., Mitsubishi Electric Corp.

- (Signal/Communication) Sumitomo Corp.

- (Track) Nippon Steel Corp., Mitsui & Co., Ltd.

- (Signal/Train Control) Nippon Signal Co., Ltd.

DMRC, the executing agency for the JICA funded "Delhi Mass Rapid Transport System Project", together with Japanese Consultants and Contractors, built up a huge urban railway network in Delhi with a total length of about 350 km in only 20 years. The Delhi Metro, which was constructed as a "High quality infrastructure development project," not only contributed to climate change countermeasures, but also gained popularity enough to be called the "Best ambassador of Japan”and became daily transportation means for the citizens of Delhi, which is said to have a scale of 30 million people.

16. Naha Airport Runway Expansion Project

- Cabinet Office Okinawa General Bureau Naha Ports and Airport Office

The Naha Airport Runway Expansion Project constructed a new runway to meet the future rapid increase in air passenger demand. The project was completed in spite of the surrounding reefs and generally shallow water, which made for difficult construction and wave conditions. The new runway will serve as a catalyst for the realization of a "strong and self-reliant Okinawa", and is expected to make Okinawa Prefecture a front-runner in the Japanese economy and make a significant contribution to the development of the Japanese economy. It was recognized as worthy of the Technology Award.

17. The Improvement of the Tokyo Station North Passage (North Passage Widening Corresponding to Change of Passenger Fuctuation and Creating New Space with High Convenience Using Existing Structures)

- East Japan Railway Company

- JR East Consultants Company

- Obayashi Corporation

The improvement of the Tokyo Station north passage which appears some problems such as congestion in the north passage inside the ticket gate, and lack of space for smoke exhaust equipment for disaster prevention. This project would include a long-span girder structure that omits the horizontal beams and intermediate columns of the viaduct to improve the passage and secure the aisle vacancy. Looking ahead to the opening of the Ueno Tokyo Line, to gradually improve the passage and secure the passage empty head.

18. Relocation of the Ginza Line platform at Shibuya Station, and Development of an Underground Plaza and an Underground Rainwater Storage Facility at the Shibuya Station East Exit

- Tokyo Metro Co., Ltd

- TOKYU Corp.

- East Japan Railway Company

In this project, related government agencies and multiple business operators established strong cooperative relationships and promoted numerous simultaneous projects from planning to construction process adjustments, such as the relocation of the Ginza Line platform, the development of an underground plaza and an underground rainwater storage facility, all the while using creativity and ingenuity to transcend project boundaries. As a result of these efforts, highly functional urban development could be achieved through the project. Thus, this project is a model case for the smooth implementation of urban renewal projects involving multiple parties.