2020 Innovative Technique Award

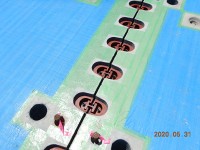

1. Development of Automatic Rebar Arrangement Inspection System Using Stereo Camera

- Kenji Yoshitake

- Akira Fujii

- Takahiro Nakano

- Kosuke Tanimura

- Shinichi Arita

This system can produce inspection records in real time on site by pushing photographing buttons by one person. And it was adopted for the formal inspection of the Ministry of Land, Infrastructure and Transport for the first time and has been introduced to multiple sites. It has also been confirmed that it can contribute not only to productivity improvement but also to safety improvement such as countermeasures for new corona infestation by shortening of working hours in high places and manpower saving. From the above, this technology can be expected to revolutionarily replace the bar arrangement inspection and greatly contribute to the improvement of productivity and safety.

2. Development of Comprehensive Quality Control Method for Impermeable Embankments

- Hiroki Sakamoto

- Hiroaki Kobayashi

- Fumio Tatsuoka

- Hideki Soda

- Takashi Obara

The conventional control of the quality of compacted fill based on field-measurements is very time-consuming, so control of the whole fill becomes very difficult. The developed technology alleviates these problems by frequent control of particle distribution, water content, compaction energy, degree of compaction and permeability by means of the ICT technology and new quality control method based on the control of the degree of saturation and control of soil stiffness to ensure low permeability and high dry density of the whole fill. This was successfully applied in the construction of the central core of a 139 m-high rockfill dam.

3. Development of “PCM Pavement”, the Technology to Repair and Reinforce the Upper Surface of Damaged Concrete Floor Slab

- Kentaro Kuraji

- Satoshi Aoki

- Masayoshi Fujiya

- Yasuko Miyazono

The concrete floor slabs that have been in service for 40 to 50 years after construction are easily infiltrated by deterioration factors such as rainwater and concerned about durability decreasing because the upper surface of the floor slabs have been scrapped by cutting machine whenever the pavement is replaced. To solve these problems, “PCM pavement” provides the repairing method applying a Dry-mix process shotcrete that enables to thicken the slabs without using mobile plant vehicles and the ultra rapid hardening polymer cement mortar that does not cause delamination with concrete.

4. Development of New Construction Technique for Tunnel Lining Using High-Fluidity Concrete with Low Cement Content “Neuro-Crete Neo”

- Kuniaki Sakurai

- Hideaki Nishiura

- Shinji Tamaki

- Hidekazu Konishi

Due to the serious shortage of construction labor force, productivity improvement in tunnel lining is expected. This will require both high-fluidity concrete which requires no compaction, and automatic concrete placing system. As the solution, we have developed two techniques. One is a high-fluidity concrete with low cement content “Neuro-Crete Neo”, which has the high-fluidity and self-compacting property with equivalent cement content to the conventional concrete. The other is a new concrete placing system which can place the concrete sequentially by automatically relocating concrete placing hoses. We have applied these techniques to a tunnel construction site and confirmed the significant increase of productivity in tunnel lining.

5. In-situ Ground Solidifying Method Using Mechanical Stirring Blades to Realize Construction with Obstacle Avoidance and Diagonal Execution (WinBLADE Method)

- Sadafumi Fujiwara

- Hiroyasu Ishii

- Tomoyuki Aoki

- Noboru Mikami

- Jun Satou

Since Japan's infrastructure development is in the mature stage, construction methods suitable for maintenance and renovation of existing facilities are in high demand. Considering this background, the construction method has been developed featuring a small and lightweight stirring blade that can be opened and closed underground. Before and after stirring work, the method can avoid obstacles such as surface pavement and pipe laying. It can also achieve diagonal construction according to the layout and shape of existing structures. Furthermore, construction forms employing different base machines are available which are suitable for diagonal/vertical executions and indoor works, respectively. Accordingly, the method can achieve in-situ ground improvement for which previous methods cannot be applied.

6. Development of Tunnel Face Projection Mapping Technology to Visualize and Share Ground Information

- Takuya Tani

- Yoshitaka Koga

- Shingo Miyamoto

- Tsukasa Koyanagi

- Tomoyuki Aoki

Tunnel face projection mapping in mountain tunnelling is a highly combined information and communication technology to visualize the ground at the face during the blasting preparation work and reproduce the ground before shotcreting as a realistic image. By projecting a color diagram to grasp quantitatively and easily the hard and soft distribution of the ground, construction efficiency such as reducing the outbreak by 50% and preventing time loss with under-blasted area is realized. This is a remarkable case that has led to productivity improvement, applying the latest video technology to civil engineering work, especially to mountain tunnelling where it is difficult to use precision equipment.

7.The development of Design and Construction Technology for Precast PC Slabs for Bridges with Cotter Joints (Cotter Slab Method)

- Teruyasu Watanabe

- Masayuki Sakurai

- Kengo Hara

- Yoshinori Takamatsu

The design and construction technology for precast PC slabs for bridges, called the "Cotter Slab Method," has been developed to replace deteriorated and damaged RC slabs for road bridges. In this method, the joint width is reduced to 20 mm by using “cotter joints”, and the panels are joined by light work such as tightening bolts and filling joints. Compared with conventional methods such as loop joints, this method has excellent features such as shortening of slab installation process, labor saving , improvement of labor safety and quality, and ease of partial replacement.